Project Description

Since 2008, China’s high-speed rail has developed rapidly. Before 2008, the high-speed railway was only an imagination for Chinese people, and they could only envy the high-speed trains flying abroad through pictures or videos. However, after entering 2008, China’s high-speed railway began to develop rapidly, which made high-speed railway become an important part of the national transportation industry, greatly solved the needs of people’s travel and national economic development, and played a huge role in stimulating domestic demand and promoting economic development. With the rapid development of high-speed rail, the Chinese brand of high-speed rail resounds all over the world, with the most complete system technology capability, the strongest integration capability, the highest operation speed, and the largest scale under construction to attract people from all over the world to visit and learn. These achievements are inseparable from the continuous iterative update and development of high-speed rail technology.

Casting plays an important role in the process of R&D and iteration of high-speed iron. However, due to the limitation of casting technology and cost, most of the castings are of the same type and mass casting, and the production time is long. However, in the iterative R&D process of high-speed iron technology, the structure of castings is complex, and the performance of materials is required to be high, and the amount is small, and the time is short, so the traditional casting is not suitable for the R & D iteration of high-speed iron.

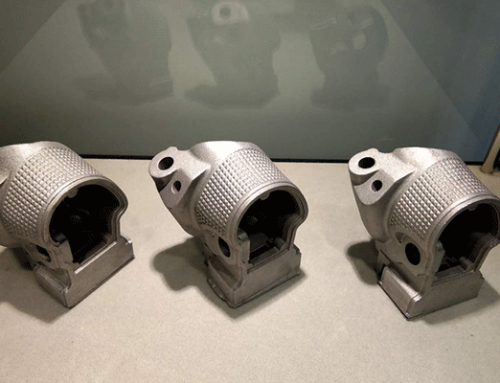

In this context, the company that is developing high-speed railway central control box technology will focus on rapid casting. Parts as large as 800 mm, wall thickness is only 2-3 mm, surface structure is complex, there are many inverted buckle phenomenon, wall thickness changes, high precision and surface quality requirements, material tensile strength requirements. Due to its constraints on the R&D process of a certain type of high-speed rail car set, the given delivery time is short and the quantity is small, which becomes a technical obstacle, and many foundries refuse or give up.

The rapid casting process is just suitable for thin-walled, complex shaped and small quantity parts. After obtaining the data chart, the rapid casting process mode of 3D printing + low-pressure casting can be used to solve these problems, such as thin wall, inverted buckle and many wall thickness changes. After two days of data optimization, it took only 4 days to complete printing and splicing, and the casting time was only 30 days. Finished the delivery of products with quality and quantity within the required time.