Technology

Aspect | Single Spot | Variable Spot | Dynamic Focus |

Component of Optical System | 355nm Solid-State Laser | 355nm Solid-State Laser | 355nm Solid-State Laser |

Scanhead(2D) | Scanhead(2D) | Dynamic Focus Scanhead (3D) | |

Beam Expander | Electronic Beam Expander | NA | |

F-theta Len | F-theta Len | NA | |

Technical Difference | 1. Solid-State Laser creates 355nm laser. | 1. Solid-State Laser creates 355nm laser. | 1. Solid-State Laser creates 355nm laser. |

Quality | Each spot in the scan plane is not the same size. The larger the printing platform, the greater the distortion(Spot roundness is less than 80% at edge). | Each spot in the scan plane is not the same size. The larger the printing platform, the greater the distortion(Spot roundness is less than 80% at edge). | The size of each spot in the printing platform is the same, the spot roundness is over 90% in middle or at edge. |

Efficiency | Standard printing speed | 80% ~ 100% faster than standard speed | 100% ~ 150% faster than standard speed |

Cost | Standard cost | Higher cost | The highest cost |

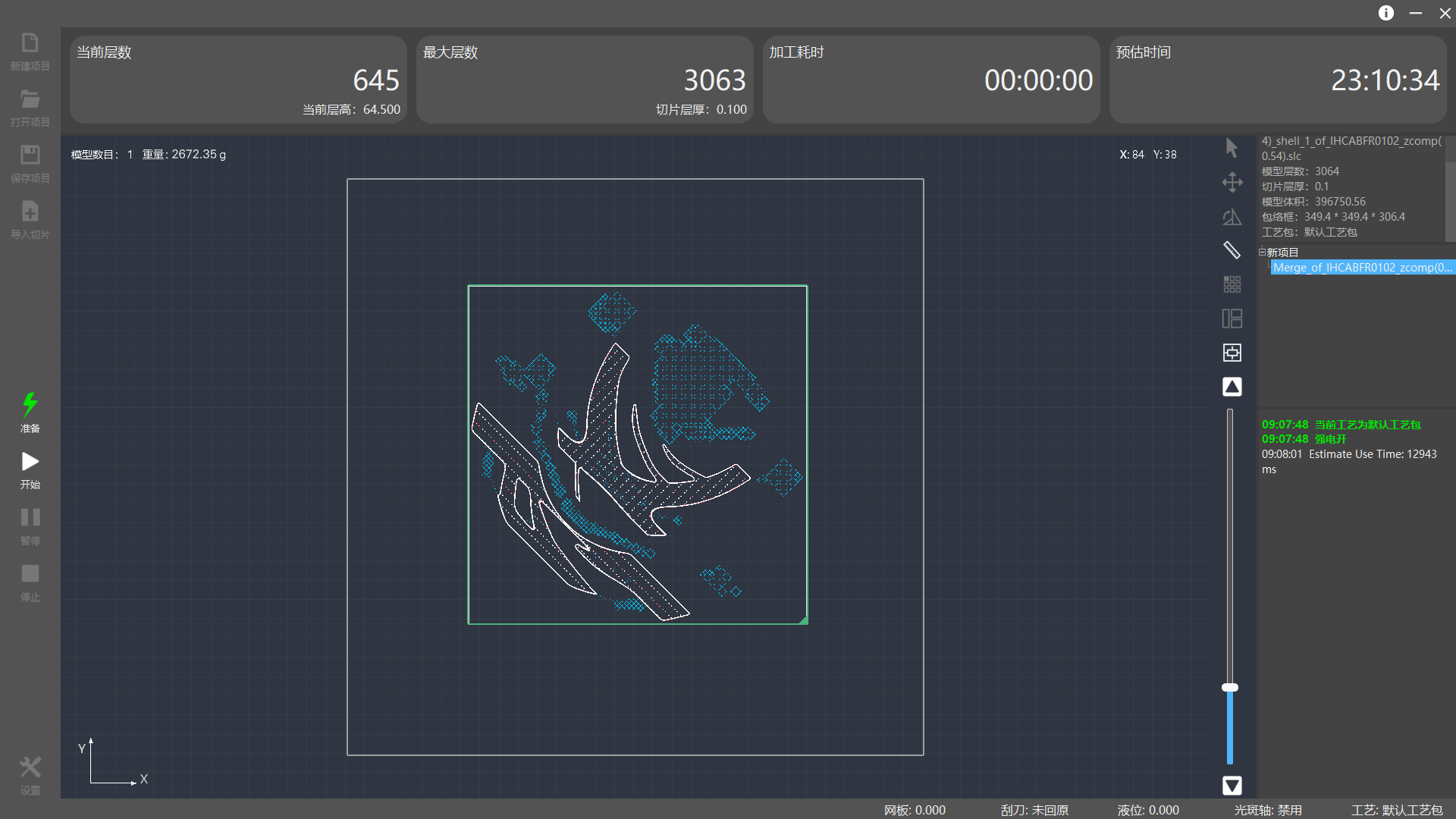

QUBEWARE PRO is a professional control software developed specifically for QUBEA 3D printer. It`s easy to operate and learn, can effectively improve work efficiency. This software supports the dynamic focus algorithm, multi-size printing platform, multiple scanning galvanometers and multiple lasers, also can optimizes path algorithms to improves print quality.

The software has a built-in parameter package, which can be directly used to retrieve the parameters in the parameter package without manual setting. The parameters of 0.1 and 0.05 can be set separately, and the process package of different resin materials can be set based on the requirements. At the same time, it`s added to estimate the printing time algorithm, the estimated time will be more and more accurate after multiple printing. Laser path scanning scheme is also added to optimize the quality of the model surface and speed up the printing time. The algorithm of liquid level adjustment is modified to make the time of liquid level adjustment shorter.