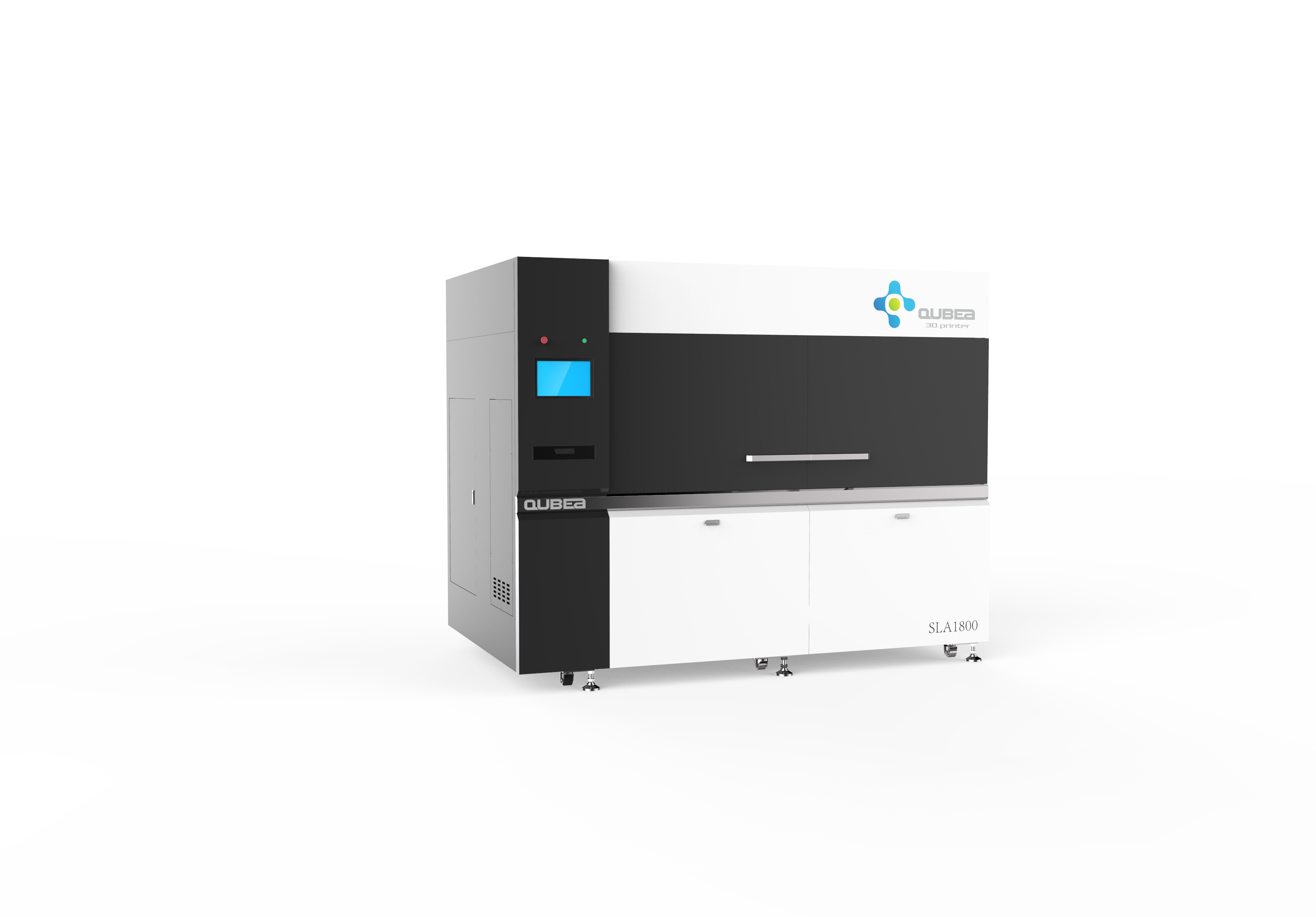

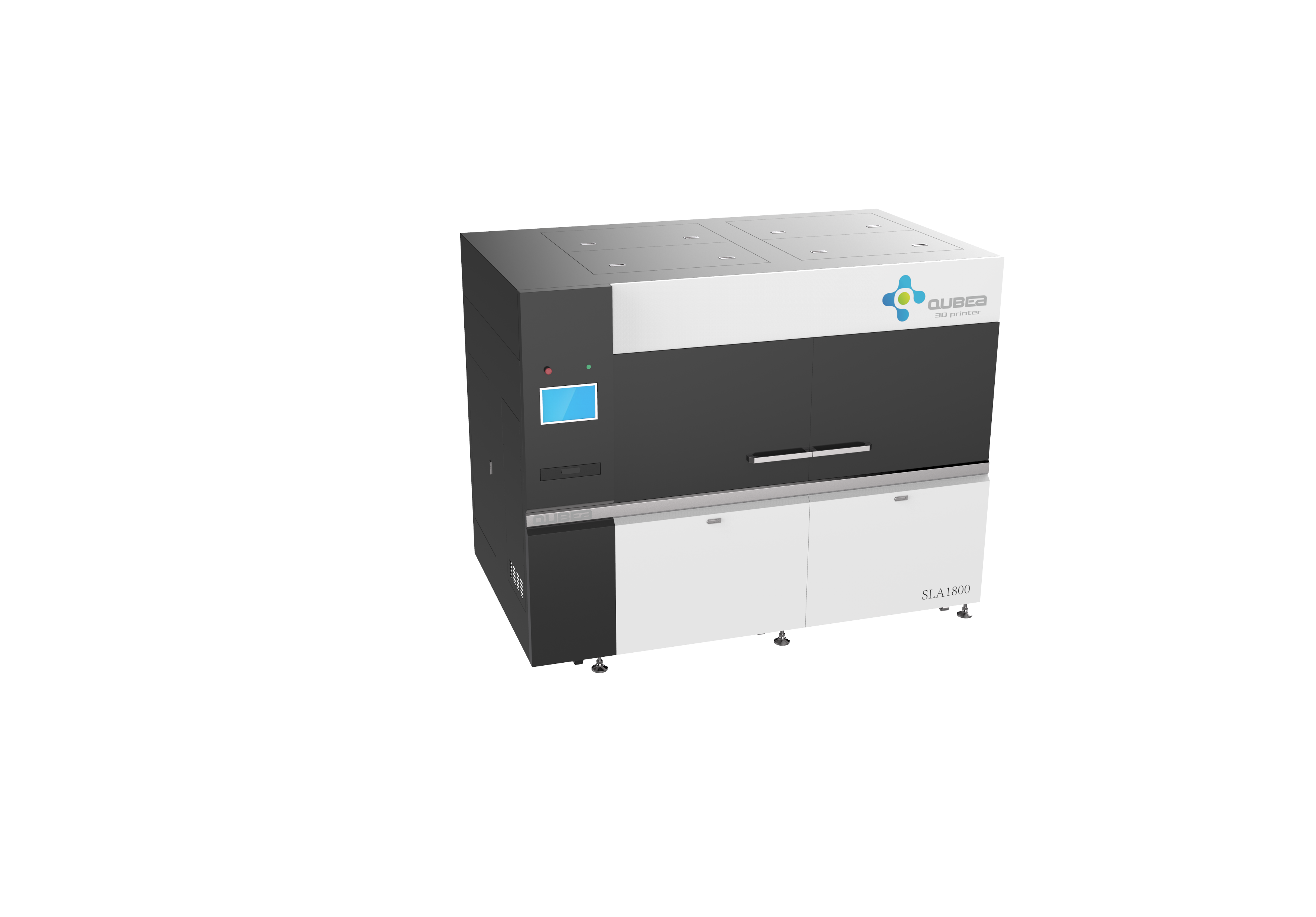

QUBEA INDUSTRIAL SLA 1800 (NEW)

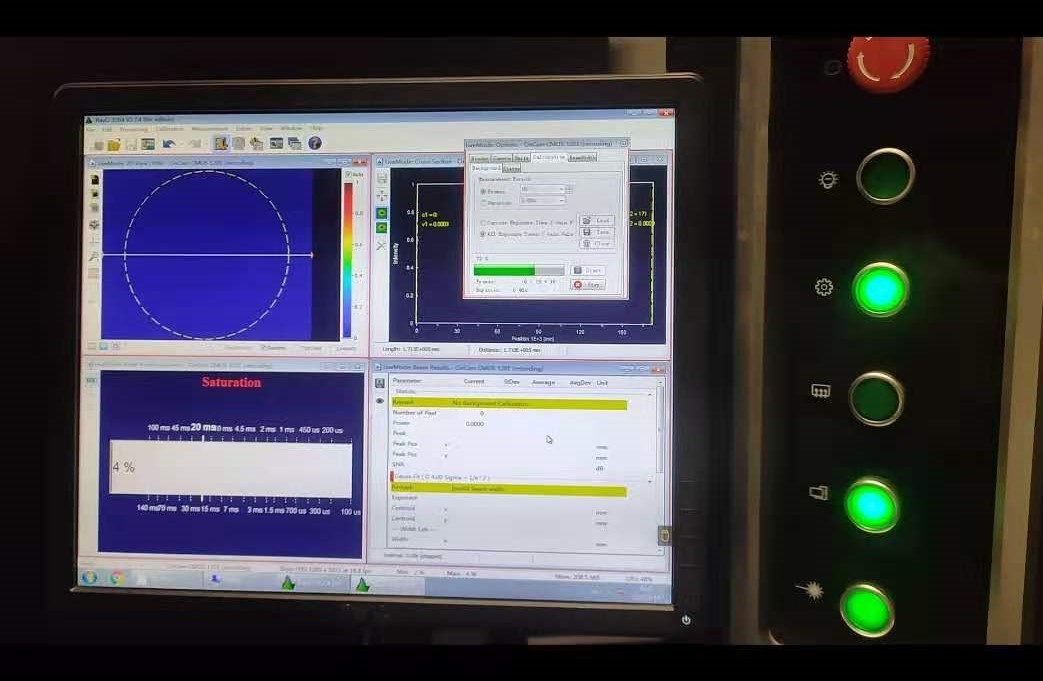

QUBEA SLA1800 is a new industrial-grade printing equipment. Assembly of high precision Dynamic Focusing System, Dual Scanning Galvanometer. The roundness of the spot can reach more than 90% in each position to ensure the printing accuracy of each position.

Benefits

- Large printingplatform can output large parts

- Duallaser and dual galvanometer system

- Fast scanning dynamic focusing system supports high speed laser scanning up to 20.0 m/s

- Automatic function to achieve more complex laser control

- Resin thermostatic control system

- Equipped with Qubeaware Pro equipment software, with a high degree of convenience and real-time monitoring

- Special scraper made of carbon fiber is provided

The Qubea SLA 1800 is a custom device for the Qubea family.

The equipment was newly released this year,

The dual laser, dual galvanometer configuration improves the scanning speed by 20%-30% during the printing process of 1800mm(X)*850mm(Y)*600mm(Z). The manufacturing speed of the parts can reach 150-500g/h, which can improve the production efficiency.

Equipped with a high-precision dynamic focusing system, the spot diameter is up to 0.8mm, and the roundness of the spot can reach more than 90% whether at the center or at the edge. In the maximum extent to ensure that each position no matter the printing of large parts or small parts precision, but also greatly accelerate the speed of printing.

SLA 1800, the best choice for mass production.

| SLA1800 Specifation | ||

| LASER SYSTEM | Number of Lasers: | Dual Laser |

| Laser Type: | Diode-pumped Solid-state Laser Nd: YVO₄ | |

| Wavelength: | 355nm | |

| Laser Power:: | 1000/2000/3000mW | |

| RECOATING SYSTEM | Coating Method: | Intelligent Positioning-vacuum Adsorption Coating |

| Normal Layer Thickness: | 0.1mm | |

| Rapid Production Layer Thickness: | 0.1~0.15mm | |

| Precision Production Layer Thickness: | 0.05~0.1mm | |

| OPTICAL & SCANNING | Light Spot (diameter @ 1 / e²): | 0.10~0.16mm(Normal) 0.10~0.80mm(Dynamic focus) |

| Scanning Galvanometer: | High-speed Scanning Galvanometer (double galvanometer) | |

| Scan Speed of Parts: | 6.0~20.0m/s(recommended) | |

| Jump Speed of Parts: | 20.0~40.0m/s(recommended) | |

| Reference Production Speed: | 150~500g/h(Super ×2 | Double Galvanometer) | |

| ELEVATOR | Repeated Positioning Accuracy: | ±0.01mm |

| Lifting Motor: | High Precision Servo Motor | |

| Benchmarking Platform: | Marble Benchmarking Platform / Casting Platform | |

| RESIN VAT | Standard Volume: | About 1400L@600mm(Z) |

| XY Production Platform: | 1800mm(X)×850mm(Y) | |

| Z Axis: | 600mm(standard)/ <600mm(customized) | |

| Max. Workpiece Weight: | 150kg@600mm(Z) | |

| Resin Heating Method: | Precision Resistance Wire Heating | |

| SOFTWARE | Control Software: | Qubeware Pro Production Software |

| Data Processing Software: | MagicsRP | |

| Data Interface: | SLC File | |

| INSTALLATION CONDITION | Power: | 200 ~ 240VAC 50 / 60Hz, single phase, 5 / 20Amps |

| Ambient Temperature: | 20-26ºC | |

| Relative Humidity: | <40%(no frost) | |

| Equipment Size: | 3.10m (W) × 1.80m (D) × 2.30m (H) (excluding computer rack) | |

| Equipment Weight: | About 4000kg | |

| WARRANTY | Laser: | 12 Months |

| Machine: | 12 Months From The Installation Date | |

| ATTACH | Carbon Fiber Scraper | |

| Hot Air Heating on Liquid Surface | ||

| Automatic Calibration | ||

| Automatic Door | ||

| Dynamic Focus | ||