Project Description

Compared with the car as a whole, tires are not so impressive, but tires for vehicles, like shoes for people, its importance is absolutely not to be underestimated. The most important step in making a tire is the manufacture of a tire mold.

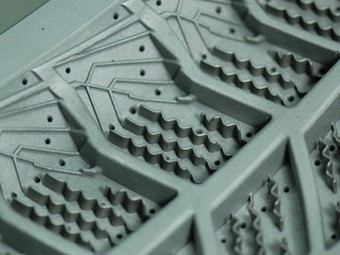

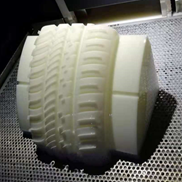

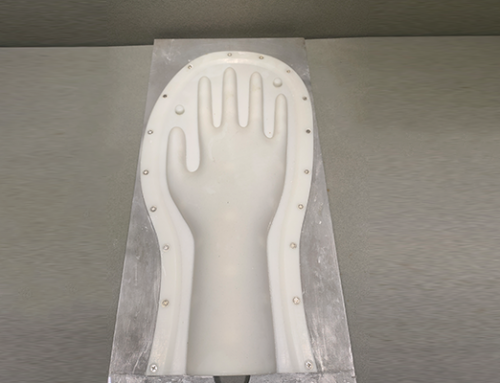

Before making a metal tire mold for production, the master mold is first made of wood substitutes, then patterns are carved on the surface, then small pieces of steel are manually inserted to deepen the grain and processed. Next, pour in the silicone solution and turn into the silicone mold. After 6-8 hours of waiting, the silicone mold is completely cured and removed to obtain the silicone mold. Then, the silicone mold is surrounded by steel plates, and the gypsum powder mixed with water is adjusted to liquid state and slowly injected into the mold frame. After solidification, the gypsum mold is obtained, and small steel pieces are inserted into the surface tire again. Finally, the metal mold is obtained by pouring the metal liquid into low-pressure die casting

In the entire production process, the most important and most costly is the production of the mother mold. The production of the tire master mold requires the use of five-axis precision carving equipment with high precision. However, because a whole round mold needs many different tool angles, it is difficult to grasp its accuracy. Therefore, it is necessary to divide a round mold into 8 pieces for processing in turn. Moreover, because the pattern on the surface of the tire mold is very thin (0.8mm thickness), it is necessary to manually insert additional small pieces of steel. While the traditional production of small steel sheet requires laser cutting machine, punch, grinding machine and other equipment.

Original way

Master Model production | Process | Manufacture Equipment | Lead Time | Manpower |

master mold | 5 Axis CNC × 1 | 1 pcs/ day | 2 ppls | |

Steel Sheet | Laser cutter × 1 | 1 set/ 0.5day | 1 ppl | |

Punching machine × 1 | 1 set/ 0.2day | 1 ppl | ||

Grinder × 1 | 1 set/ 0.2day | 4 ppls | ||

Steel install |

| 0.1 day | 2 ppls | |

| 1 set tire mold (8 pcs) need 9 days,10 peoples | |||

The QUBEA3D printing method does not require the use of five-axis CNC, laser cutting machine, punch press, grinding machine and other equipment. Only one 3D printing device is needed to complete the production directly, which greatly reduces the cost.

Master Model production | Manufacture Equipment | Lead Time | Manpower |

QUBEA-SLA600 × 2

| 8pcs/ 3days | 1 ppls | |

1 set tire mold (8 pcs) need 3days,1 peoples | |||

Under the quick production mode of Qubea industrial 3D printing equipment, the printing layer precision is up to 0.1mm, and the precision production layer thickness is up to 0.05mm, which can directly and clearly print the surface lines of the tire mold. Moreover, it can print more than one mold at a time, avoiding the precision problem caused by the difference of equipment, effectively shortening the time of mold opening and completing the production of master mold with both quality and quantity.