Quick Casting

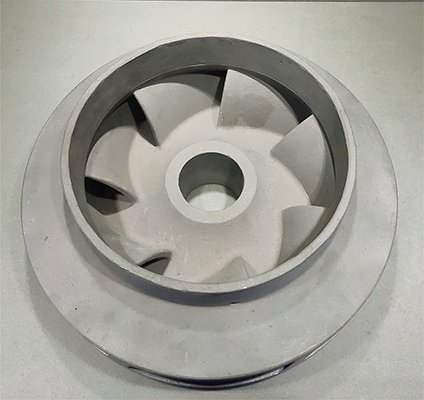

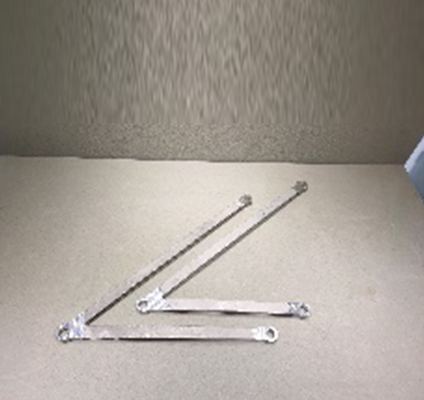

Quick casting is based on the traditional investment casting and combined with 3D printing to launch a quick casting process without die sinking. The casting time of quick casting is shortened from 45 days to 15 days, and since it does not require die sinking the high cost is largely saved,which is reduced by about 50%.

Our Background

Investment casting is also called lost-wax casting. The castings fabricated by this technique have high dimensional accuracy and polished surface, which reduces the machining work. It can also cast complex castings of various alloys, especially high temperature alloy castings, which can ensure the consistency of castings and avoid residual cutting marks caused by machining, so it is suitable for mass production. However, the production cycle is long, need to at least 45-60 days to cast a model. Besides, due to the limitation of the production process, it is impossible to produce thin-walled, special-shaped and complex models.

Under the background of the long production cycle and high cost of die sinking, a large number of professional casting factories are only willing to accept bulk orders and the type of finished products is single. For those who have the demand for small-batch casting, they have difficulty in finding a factory for a corporation because of the high cost, pushing enterprises that need R & D in a disadvantageous position.

Taking Action

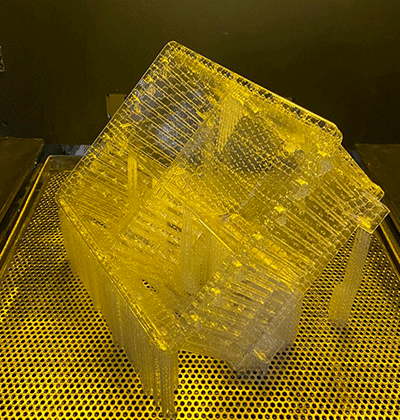

QUBEA has been committed to innovation and integration of new 3D printing technology with traditional industries since the establishment. We try to combine 3D printing with casting technique after the finding that there is still demand for the small-batch casting in the market.

3D printing is to output models or parts which are processed by professional software in advance by 3D printing equipment. 3D printing is designed to replace the traditional “wax casting mold” as its advantages of fast molding speed, high printing accuracy, and printing of special-shaped and thin-walled parts. In addition, it also makes up for the disadvantages of the conventional investment casting and greatly shortens the production cycle.

For the purpose of the better replacement of the conventional wax casting mold, we begin to study new printing materials that can be directly gasified without demolding during casting. Resin, suitable for casting, is what we have studied after a long term of research and testing. Since then, 3D printing and foundry industry began to integrate.

Founding of foundry factory

In 2019, it has improved the infrastructure construction of casting, the recruitment of professionals, the procurement of professional casting software, training and other important measures.