Aircraft handle

Aerospace technology is a symbol of national defense strength, and competition among countries is extremely fierce. As a result, countries are trying to develop newer weapons at a faster pace to ensuring an invincible position in the field of defense. quick casting technology can greatly shorten the manufacturing process, quickly transform the theoretical model into a solid model, greatly shorten the product development and manufacturing cycle, and accelerate the product iteration and update.

Problems

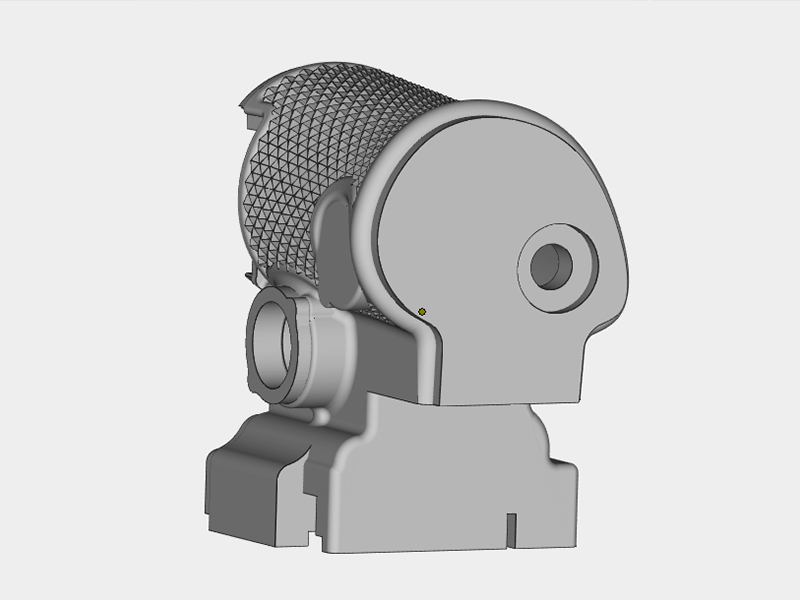

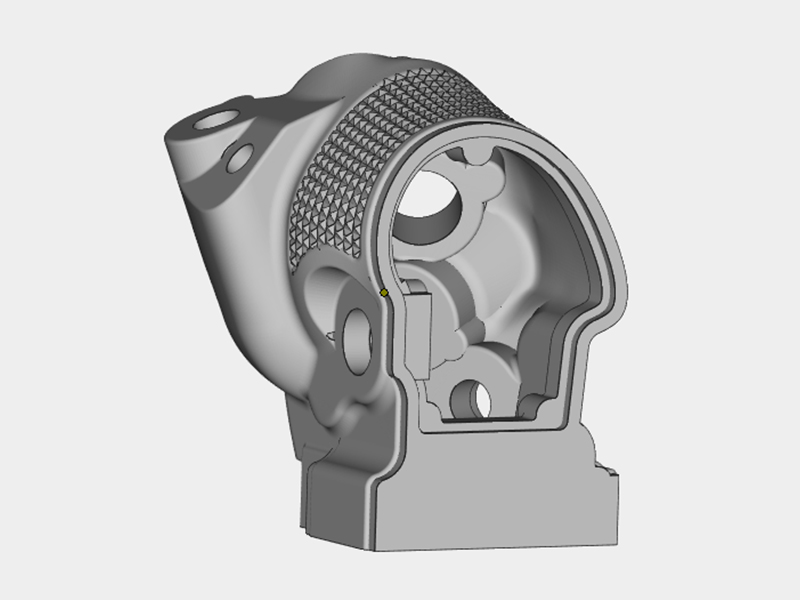

This aircraft handle part is used in a certain type of aircraft parts, because its internal structure is complex, and have undercut, it`s cannot make the whole mold; The surface has the characteristics of knurling, these knurling is very small, once the traditional casting is incomplete, cannot use welding repair. Therefore, the failure rate of traditional casting is very high and the manufacturing cycle is long. The demand quantity is small, not suitable for the traditional casting.

Solution-Use the Quick casting

By using the quick casting technology, the model is first transformed into a data model, and the model structure is judged by using professional design software and combining with the database data. On the premise of ensuring the performance, an optimization scheme is proposed for the place where the structure can be optimized. Print out after data processing. Using 3D printing technology to print casting model, time is fast and cost is low. It took only a day to print these model airplane handles.

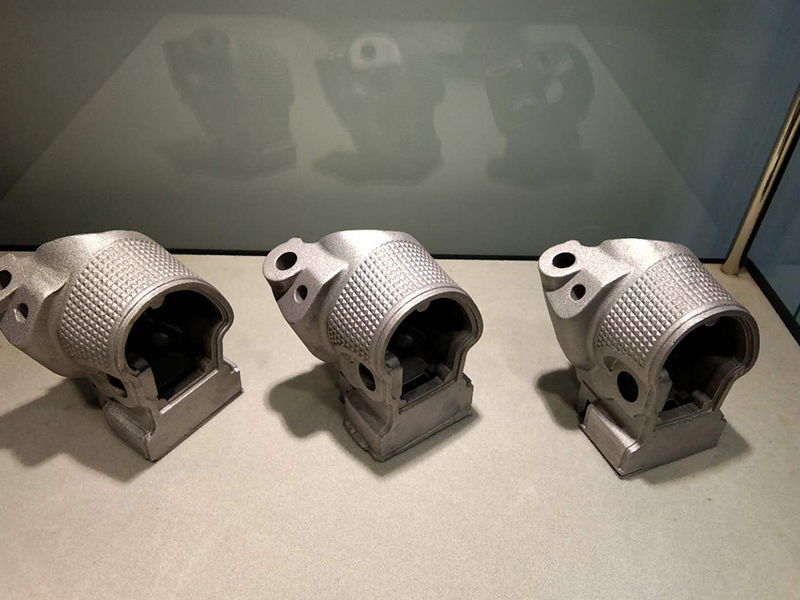

After the model is printed, professionals conduct the castability analysis and casting simulation to ensure the quality of casting products and improve the success rate of casting. Finally the casting is ready. The entire production cycle is only 20 days. The products have high precision, smooth surface, clear knurling details, complete internal structure and low failure rate. The customer was very satisfied after seeing the product. The effect of the rapid casting was beyond his imagination.

Quick casting is after a long time of research and development and verification, using professional 3D printing casting materials, together with professional technicians to evaluate and analyze each casting piece. it can produce all kinds of complex casting parts in a short time and reduce the failure rate.